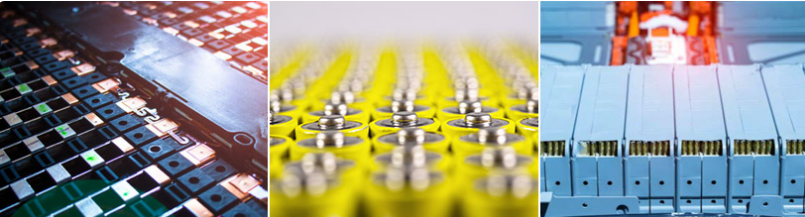

The United States has announced plans to establish a domestic supply chain for lithium-ion batteries, which are vital for electric vehicles and renewable energy. The company’s new goal is to have almost everything within its borders, from mining to manufacturing to battery recycling, by 2020. The U. S. Department of Energy Today released a “national blueprint” outlining how it plans to improve U. S. capacity to produce lithium-ion batteries. Demand for such batteries has skyrocketed for Electronics and electric cars. The refurbished grid also requires large batteries to accommodate the increasing use of solar and wind power. In its blueprint, the Department of Energy even provides a reason for battery-powered airplanes to fly. “Our supply chains in the transportation, utility and aviation sectors will become vulnerable and will be constrained by other companies’ key technologies, ” said the US, now a small player in the global battery industry. China dominates battery manufacturing and the mineral supply chain. On its current trajectory, the supply of electric vehicles in the lithium-ion battery is expected to be less than half of expected demand by 2028. “these projections suggest that U.S. companies will not benefit from domestic and global market growth, which is a real threat, ” the blueprint said. “Our supply chains in the transportation, utility and aviation sectors will be vulnerable and constrained by other companies’ key technologies, ” according to the Department of Energy, much of what is holding the United States back is the lack of a national strategy. So in an effort to turn things around, the Department of Energy laid out the priorities for federal investment in this technology over the past decade. One of the biggest problems to solve is how to get enough of the key minerals. Shortages of lithium, cobalt and nickel for batteries are imminent. To make matters worse, they are mined in only a few places and labour and human rights abuses are widespread. This makes it urgent to find new mineral resources and design batteries that use less of these materials.

The United States is already scrambling for lithium, and the Department of Energy’s new plan is likely to speed up domestic mining. The Department of Energy also calls for mandatory recall so that battery makers can eventually harvest more materials from used products. In the long run, the doe hopes to find a cobalt and nickel free lithium-ion battery by 2030. (Tesla announced last year that it would make the cathode of electric car batteries cobalt-free) . The U.S. Department of Energy plans to lend $17 billion to U.S. electric car manufacturers. It also intends to deploy additional large-scale energy storage facilities at federal bases. It also issued new guidelines requiring federal contractors and grantees to manufacture in the United States the products they are researching and developing, including any products related to advanced batteries. The U.S. may need to figure out how to produce more of its own products as part of a broader push by the Biden administration to develop more domestic supply chains. In addition to lithium-ion battery, they focus on key minerals, semiconductor chips and pharmaceuticals. The United States government today conducted a larger assessment of all of these supply chains and announced the formation of a new task force to stem supply chain disruptions. After the COVID-19 outbreak exposed serious flaws in the global supply chain, the working group focused on finding short term solutions. In the long run, the US may need to figure out how to produce more of its own. The Biden Administration will allocate $100 million to state-level apprenticeships, which will help create a workforce for new domestic supply chains. “For decades, we have treated labor as a cost to be managed, not an asset to be invested, and that has weakened our domestic supply chain, ” Sameera Fazili, deputy director of the National Economic Council, said at a briefing today. “These reports clearly show that we need to take action. ”

Post time: Jun-16-2021